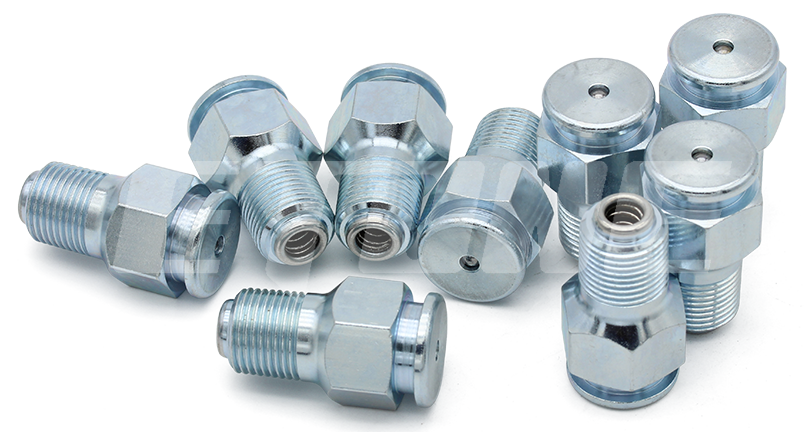

• This grease fitting with giant button, double ball check and bleeder groove is used on many brands plug valves.

• Bleeder Groove allows any valve body pressure to release as fitting is unscrewed from the valve.

•Double ball check ensures safety for high pressure applications.

Our Grease Fitting is designed for high-pressure oilfield applications, ensuring reliable lubrication and pressure sealing for plug valves. With double ball check technology and a bleeder groove, this fitting guarantees safety, durability, and efficiency in extreme conditions.

Versatile Thread Options – Available in 3/8-18 NPT (tapered) and 3/4-16 UNF (straight) to fit various plug valve models.

♦High-Pressure Durability – Withstands 10,000 to 15,000 PSI, ensuring reliable performance in extreme oilfield conditions.

♦Secure Double Ball Check – Prevents leakage and enhances safety in high-pressure applications.

♦Bleeder Groove for Pressure Release – Safely releases valve body pressure when unscrewing, preventing hazards.

♦Corrosion-Resistant Materials – Made from SS316, SS304, AISI 4140, offering excellent durability in harsh environments.

♦Customizable Thread & Coatings – Available in various thread types and surface finishes to fit diverse oilfield needs.

Etone provides double ball grease fitting can be used in high pressure plug valves or regulating valves. The double ball grease fitting is with giant button head which fits button head grease gun coupler. The double ball check ensures safety in high pressure applications. These grease fitting designs do not fit the vent caps. We have two types of double ball grease fittings. One is with NPT (Tapered) thread and the other is with UNF (straight) thread. The UNF thread is with pressure relief groove which allows venting excess pressure when discharging the fitting, when after completing the greasing procedure or when in the event of a leak.

✅High-Pressure Resistance – Handles 10,000 to 15,000 PSI, ensuring stable performance in demanding environments.

✅ Double Ball Check Design – Prevents leakage and enhances operational safety under extreme pressure.

✅ Bleeder Groove – Allows controlled pressure release when unscrewing the fitting, minimizing risks.

✅ Premium Materials – Made from SS316, SS304, and AISI 4140 for exceptional corrosion resistance and durability.

✅ Versatile Thread Options – Available in 3/8-18 NPT (tapered) and 3/4-16 UNF (straight) to fit various plug valve models.

✅ Customizable for Your Needs – Multiple material and coating options available to meet specific operational requirements.

*We respect your confidentiality and all information is protected.

lf you find any issue with this form, please directly contact pe@etoneoil.com

✔ Optimized for Plug Valve – Designed specifically for plug valves in drilling and extraction systems.

✔ Sealing Performance – Ensures smooth lubrication and pressure containment, reducing maintenance.

✔ Direct Factory Supply – Competitive pricing and consistent quality control for reliable performance.

Our Grease Fitting is designed for high-pressure oilfield applications, ensuring reliable lubrication and pressure sealing for plug valves. With double ball check technology and a bleeder groove, this fitting guarantees safety, durability, and efficiency in extreme conditions.

Upgrade your plug valve performance with our high-quality Grease Fittings. Contact us today for bulk orders and custom requirements!

Contact Oilfield Spare Parts today for pricing, availability, and customization options to meet your specific needs!

*We respect your confidentiality and all information is protected.

lf you find any issue with this form, please directly contact pe@etoneoil.com