• Made with tungsten carbide for superior wear and corrosion resistance in harsh drilling environments.

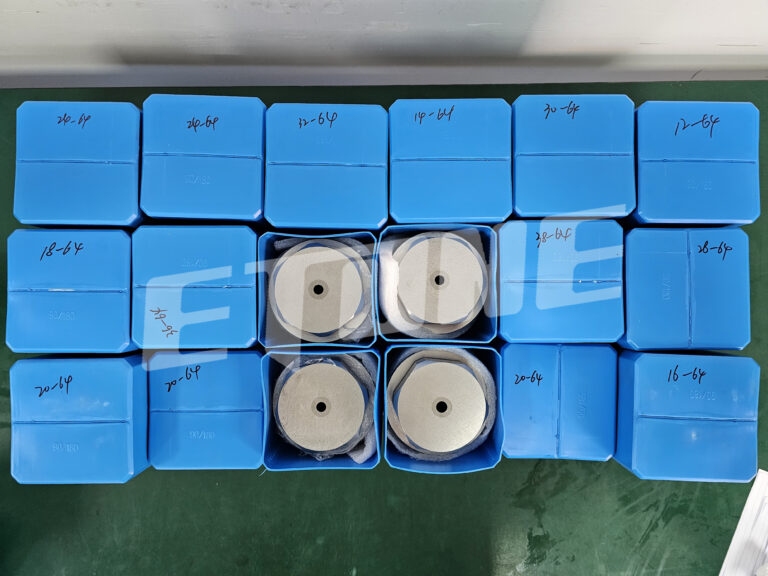

• Available in 12/64″ to 40/64″, compatible with major choke valve brands like Cameron and Big John.

• Precision-engineered for stable flow control and extended service life in high-pressure oilfield operations.

• Factory-direct supply with fast delivery and flexible OEM/ODM support for bulk orders.

Etone’s beans are made from premium materials including tungsten carbide, stainless steel, and high-strength alloy steel, ensuring maximum wear resistance, corrosion protection, and extended service life. All components are produced according to API standards, under a strict quality management system.

Our flow beans are fully compatible with Cameron, Big John, and other leading choke valve brands. Standard sizes range from 12/64″ to 40/64″, with OEM customization available upon request.

♦High-Performance Materials: Tungsten carbide inserts for extreme durability and erosion resistance.

♦Precise Flow Control: Engineered for accurate pressure regulation and consistent flow.

♦Wide Compatibility: Fits most industry-standard choke valves and manifolds.

♦API-Compliant Manufacturing: Strict quality control with full traceability.

♦Factory-Direct Supply: Fast delivery and support for bulk or custom orders.

API‑Q1 Certified Manufacturing: In-house ISO 9001 and API-certified factory ensures consistent quality.

In-stock and Fast Delivery: Common sizes (e.g., 24/64, 32/64, 48/64) available for immediate shipment; custom sizes produced with short lead times.

Engineering Support: Datasheets, MTR samples, and compatibility charts available. Technical guidance provided by our team.

*We respect your confidentiality and all information is protected.

lf you find any issue with this form, please directly contact pe@etoneoil.com

*We respect your confidentiality and all information is protected.

lf you find any issue with this form, please directly contact pe@etoneoil.com