Etone’s check valve repair kit of products enables customers to achieve maximum life and value from their flowline systems throughout a complete range of applications. The repair kit are used to isolate well-servicing equipment from highpressure treating fluids during fracturing applications. Offered in several different primary models as below. Consult factory for configurations.

Working Pressure : 15000PSI

Service Rating: Standard

Connect: Fig.1502, hammer unions, DuraLock hubs

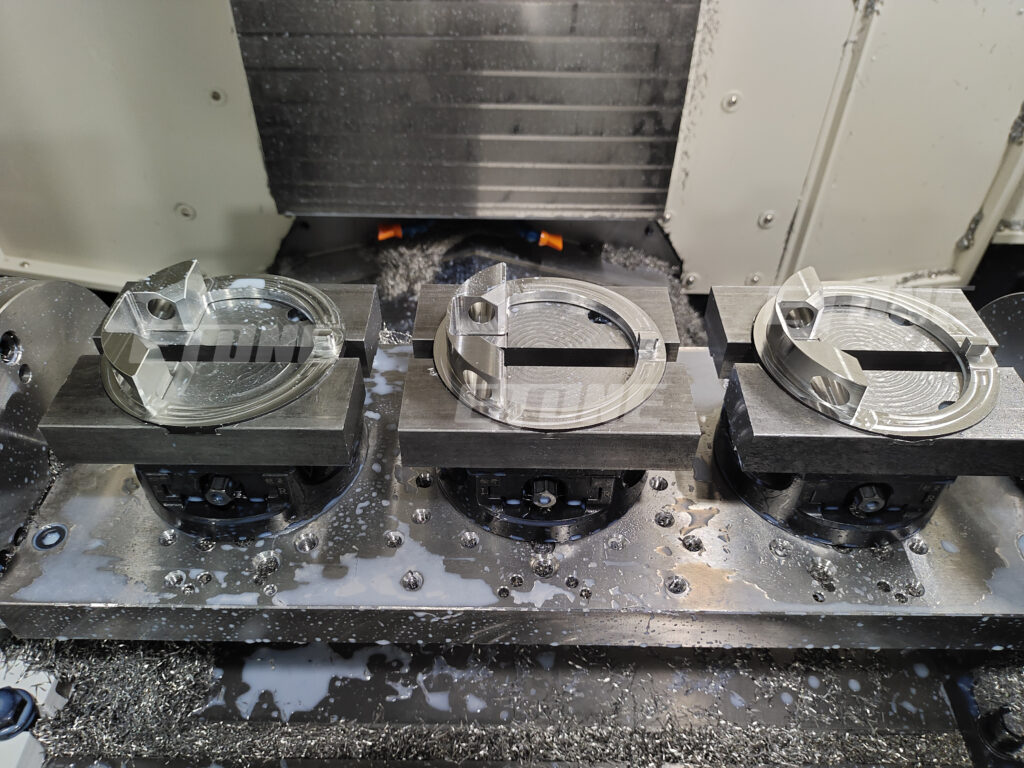

Manufacturing Process: CNC milling+CNC turning+heat treatment

•High precision internal component materials offer superior longevity reducing total cost of ownership

•Maintenance intervals are reduced for streamlined operations and minimized downtime

•Optimized internal body and component geometry to improve flow and mitigate washout

•Offered with multiple end connections

•Heat treatment(H900) makes it more suitable for high-strength, high-wear or high-temperature environments

•Improved sealing: The rubber coating (such as rubber or polyurethane) can better conform to the valve seat, reducing the risk of leakage and improving sealing efficiency.

•Corrosion resistance: In the oil and gas industry, the working medium may be corrosive. The rubber coating helps protect the metal substrate, extending the service life of the component.

•Impact and wear resistance: Under high pressure or high flow conditions, metal parts are prone to impact and wear. The rubber coating provides a cushioning effect, reducing damage.

•Adaptability to extreme temperatures: Special rubber materials can maintain elasticity under extreme temperature conditions, ensuring that the check valve functions properly in various working environments.

Working Pressure : 15000PSI

Service Rating: Standard

Nomnal Size: 3″

Connect: fig1502 hammer union end connection

Manufacturing Process: CNC milling+heat treatment

•All processes including CNC machining and heat treatment are strictly controlled and full trackable in according with standard

•Simple structure,the kits can be easy changed

•Stop the return flow from high pressure piping

*We respect your confidentiality and all information is protected.

lf you find any issue with this form, please directly contact pe@etoneoil.com

Get an instant quote or let us know what you’re looking for, and we’ll get back to you soon!